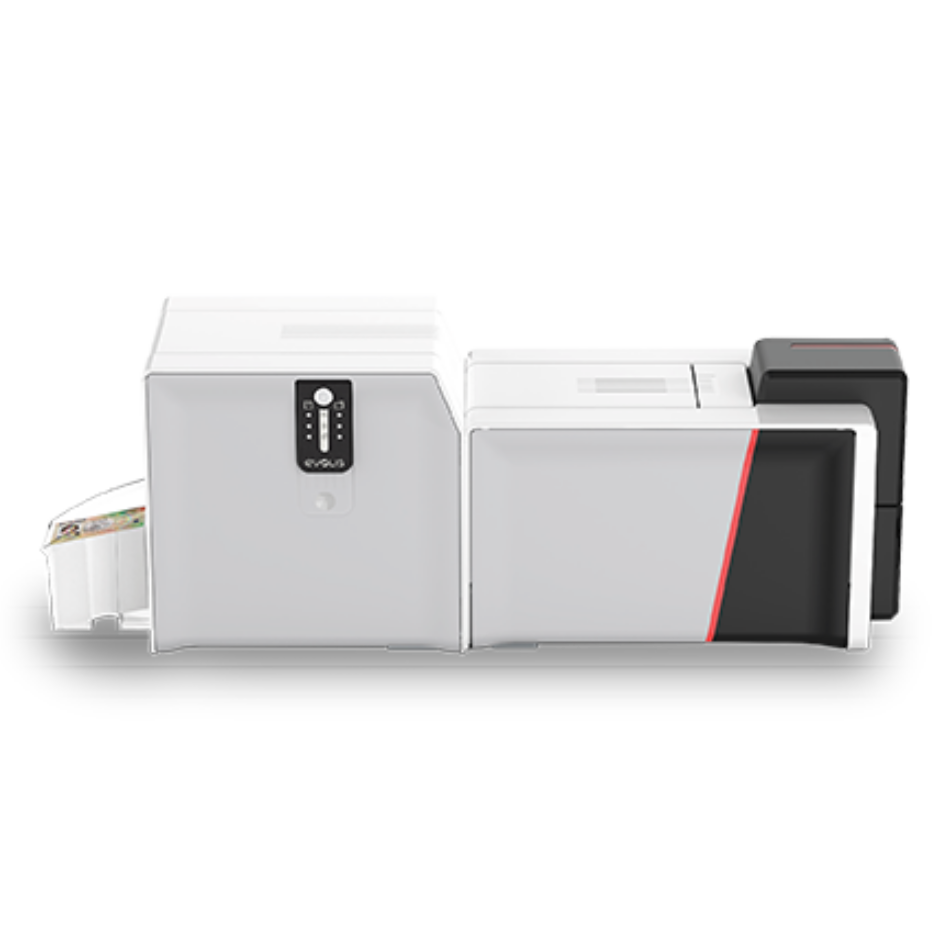

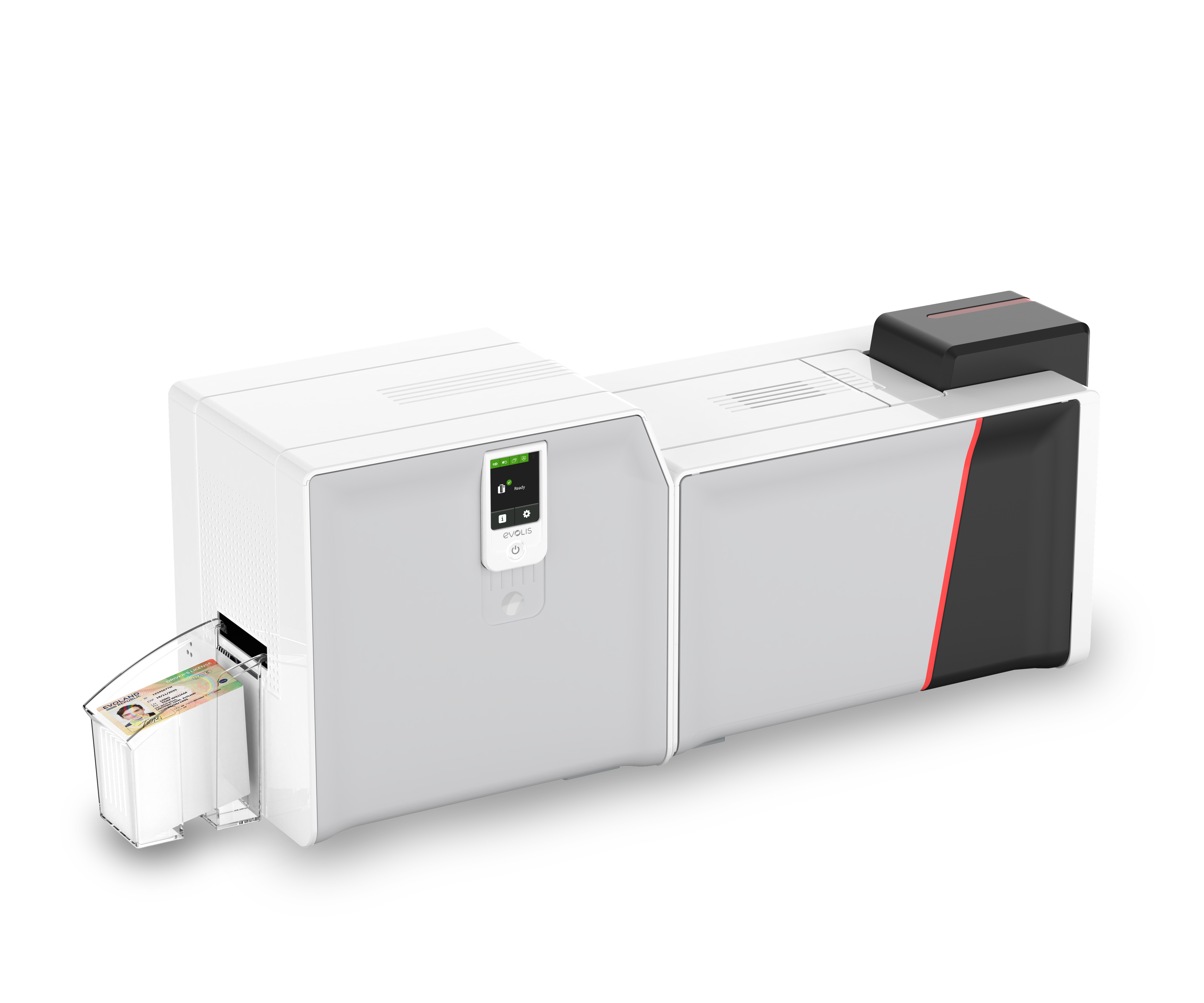

CLM Card Lamination Module

The card lamination module enables you to protect all your personalized cards for up to 10 years by applying a film. It can be used alone or in conjunction with Primacy 2 or Agilia card printers.

- High-quality lamination: single- or double-sided, integrated card flattener, speed up to 215 cards/hour.

- Wide choice of films: full range of high-capacity varnishes and patches, with or without holograms.

- Intuitive use: LED panel or LCD panel with QR code for user guidance, easy access to consumables.

Evolis card lamination module: a must for protecting all your cards

The CLM (Card Lamination Module) can be used in stand-alone mode or in conjunction with your card printer to provide additional protection for your graphically personalized and encoded cards. It protects them (single-sided or double-sided) from wear and tear associated with their use (dust, UV, rubbing, scratching, etc.), and from the risks of fraud and forgery. Depending on your needs and the level of protection required, you can choose between different types of film and security elements, which can be combined with each other.

The extension of your card printer

After personalization, your cards are laminated. This first stage of graphic personalization (visual elements in color or monochrome) and electrical personalization (encoding) is carried out by your printer. By adding a card lamination module, you protect the printed card (single- or double-sided), before handing it over to the cardholder.

The Evolis CLM is available as an option on our product Primacy 2 and Agilia (retransfer technology) printers.

Varnishes and patches: what uses for what benefits?

There are two types of varnish and patch:

- Blank and transparent films: the film is devoid of any additional elements. Its main function is to add durability to the printed card.

- Films with security features: in addition to extending the life of the cards, this film will also increase their level of security.

Blank and transparent films

Varnish

Covers 100% of the card surface, edge to edge. Its thickness gives it an estimated durability of 2 to 3 years.

Patches

Covers 92% of the card surface and is thicker. It therefore offers superior durability, up to 10 years depending on thickness.

To suit every need, it is available in different forms:

- Full version: the same panel is repeated continuously. Ideal for laminating complete boards.

- Pre-cut version: the panel is pre-cut in specific places so that the patch cannot settle on it. This enables lamination of smart cards, for example (single-sided).

- Alternating version: two different panels alternate. They come in different versions to suit the specificities of front and back. This makes it possible to laminate smart cards with magnetic stripes, for example, or even to alternate a holographic patch on the front and a transparent one on the back.

Films with security elements

Films with security features is used in the same way as blank film but has been pre-treated to incorporate holograms. This visual element makes it easy to check the card at a glance.

What’s more, the holographic effect has the particularity of reacting strongly to light. This prevents photos from being taken or scanned effectively, thus limiting the risk of forgery.

Comparison chart: how to choose between a varnish and a patch?

| Varnish | Patch | |

| Thickness | 3 microns | 0.5/0.6 mil 1.0 mil |

| Area covered (full version) | 100% | 92% |

| Durability provided | Between 2 and 3 years | Up to 10 years depending on thickness |

| Version with hologram | Yes | Yes |

| Full version | Yes | Yes |

| Pre-cut version | No | Yes |

| Alternating version | No | Yes |

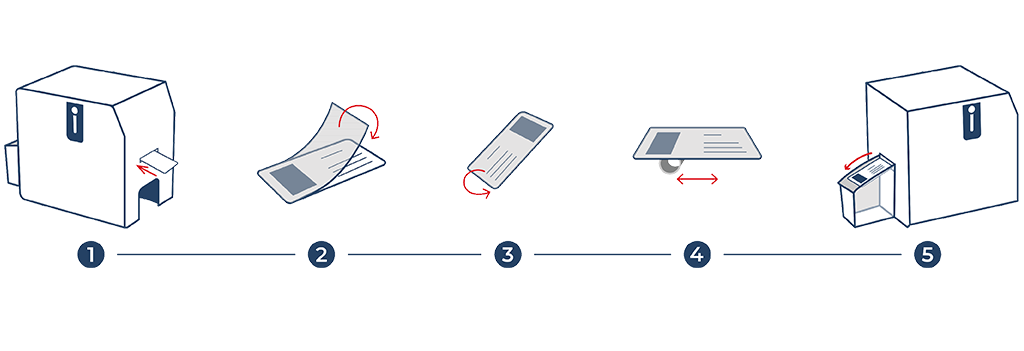

How does the card lamination module work?

Lamination is based on a thermal transfer process and consists of several stages.

- The card is transported in the module to the roller, which is heated to 180°C

- The film is unwound from the roller and glued to the card

- In the case of double-sided lamination, the card is turned over and the previous operation repeated

- It then passes through the leveller, which adjusts its planarity by applying pressure

- Finally, the card is ejected into the hopper, ready for use

The module reaches a speed of 215 cards/hour single-sided and 110 cards/hour double-sided.

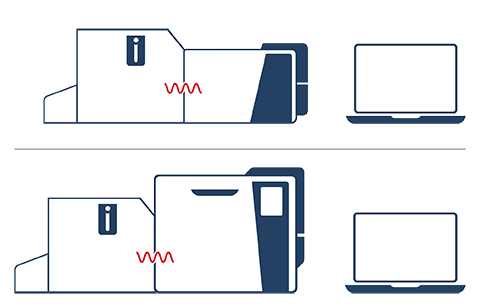

For use with a card printer or independently

The CLM is a product that can be used on its own, in conjunction with a card printer, or by installing two modules in succession. Whichever configuration you choose, installation and commissioning is straightforward.

Card Lamination module associated with a card printer

The Evolis card lamination module is available as an option on our product Primacy 2 and Agilia (retransfer technology) printers. Combined, they become a complete system capable of printing, encoding and providing enhanced card protection in a single pass. This solution also enables parallel working: while one card is being personalized in the printer, the other is being laminated. This optimizes issue times for mass production runs.

The CLM is plugged into the mains and communicates with the printer via infrared, thanks to the kit supplied as standard.

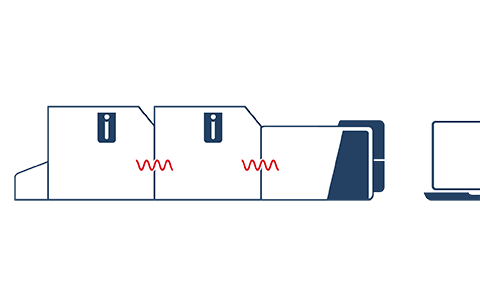

Two modules combined with a card printer

Two card lamination modules can be linked together. You can associate them with Primacy 2. You can then use different films in each of the two modules. If you need very specific security features, it’s often more economical to use this solution, especially for high-volume issues.

The CLM are plugged into the mains and

communicate with each other via infrared, thanks to the kit supplied as standard.

Laminator module alone

The card lamination module can operate as a stand-alone, card-to-card insert. You can then protect cards previously printed with any thermal transfer, color sublimation or retransfer printing solution.

The CLM are plugged into the mains and communicate with each other via infrared, thanks to the kit supplied as standard.

Evolis control panel and driver for intuitive operation

The CLM is easy to use. It benefits from the software environment developed by Evolis, renowned for its ease of use and ergonomics. Its driver, the Evolis Premium Suite, makes it very easy to set parameters (speed, temperature, lamination mode, card type, standby, etc.).

It also comes with an LED control panel as standard. This enables you to check at a glance the status of your card lamination module (operation, cleaning cycle to be launched, status of a card, film, etc.). And if you combine it with the Primacy 2 printer, you can choose the color LCD control panel option for additional assistance, including user guidance via QR code.

Built to last

Like all Evolis products, the CLM has been developed to offer you the longest possible service life.

To ensure its smooth operation and longevity, we recommend regular cleaning sequences, using Evolis cleaning kits. Your module tells you when to start them, via a display on its control panel, and guides you through the driver to perform the various operations with ease. It comes with a 3-year warranty, with the possibility of a 1-year warranty extension.

Repairability of the module is also a criterion of longevity. The heating roller, the product’s key component, can be purchased separately and simply replaced on site.

CLM Card Lamination Module

| Single-side and dual-side lamination |

| Integrated debower (card flattener) |

| Lamination speed: up to 215 cards/hour (depending on the associated printer) |

| Large choice of laminates: Varnish, Patches with or without holographic element. Possibility to create custom holograms. |

| Use associated with a card printer (Primacy, Agilia) or in standalone mode |

| Connection through infrared (for Agilia & Primacy 2) |

| Warranty: 3-year | 1-year warranty extension available |

Pick in the below list the appropriate reference according to the use : stand-alone or associated with Primacy or Agilia printers.

| Part number | Description |

|---|---|

| S10212 | Card Lamination Module with LED Works with Primacy, Primacy 2 or in stand-alone. For stand-alone use, order USB cable (reference: A5017) |

| S10252 | Card Lamination Module with LCD display Works only with Primacy and Primacy 2 printers |

| S10474 | Card Lamination Module with LED Works only with Agilia retransfer card printer |

Also to be discovered :